1,Product Description

Heat Resistant Seal P3 2.8*1.9 Oring Custom

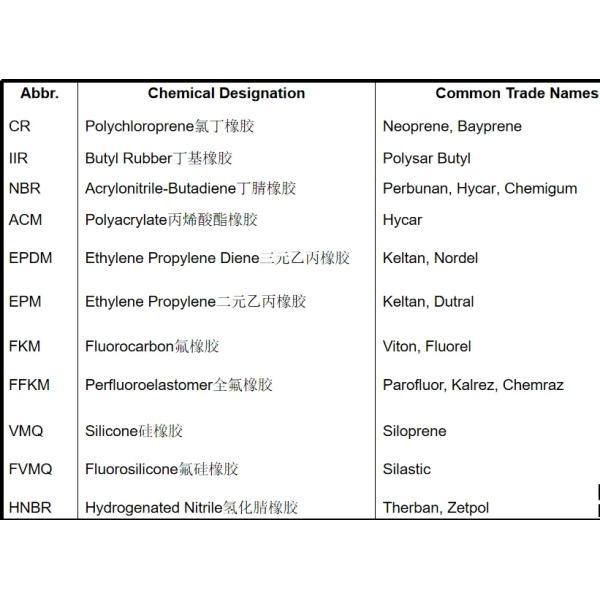

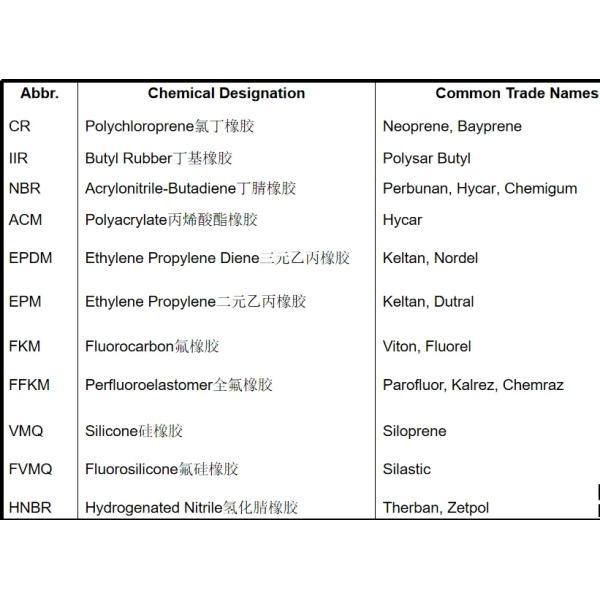

EPDM/SILICONE/NBR/ACM/HNBR/FKM Rubber O Ring

Advantages:

1.Seal over a wide range of pressure, temperature and tolerance

2. Broad selection of materials

3. Ease of service

4.No critical torque on tightening, therefore unlikely to cause

structural damage. In many cases it can e reused.

5.Not effected by compression as much as flat gasket, because metal

to metal contact is generally allowed for.

6.High cost-effective

Major Stages of Quality Control at KELONG

1: In-coming compounds

2: Batch identification (Traceability Record)

3: Batch Testing (Data Log: Hardness, S.G., Tensile Strength,

Modulus, Elongation)

4: Pre-forms (spc control)

5: Tooling

6: Molded parts (time, temperature (spc), pressure)

7: In-process checks (documentation)

8: Finished parts - dimensions checked on a Micro Vu non-contacting

CMM and micrometer

2,Material analysis

NBR

Temperature range: -30°C to 125°C Hardness: 40-90A Color:

Customizable Application: Excellent oil resistance Advantages:

Excellent

oil resistance and stability, widely used, affordable price

FKM

Temperature range: 20°C to 250°C Hardness: 50-90A Color:

Black/brown/green, other colors can be customized Application:

Excellent

oil and chemical resistance Advantages: Wear resistance, acid and

alkali resistance, high temperature resistance.

SILICONE

Temperature range: 60°C to 225°C Hardness: 25-90A Color:

Red/transparent (clear)/white, etc. Application: Food grade

Advantages:

Good heat resistance, cold resistance, lubricating oil resistance,

and water resistance.

EPDM

Temperature range: 50°C to 150°C Hardness: 40-90A Color:

Customizable Advantages: Excellent ozone resistance, heat

resistance,

steam resistance, cold resistance, and LLC resistance.

NR

Temperature range: -44°C to 120°C Hardness: 60-90A Color:

Customizable Advantages: Excellent mechanical strength and fatigue

resistance.

HNBR

Temperature range: -30°C to 160°C Hardness: 50-90A Color: Black,

other colors can be customized Advantages: Excellent ozone

resistance, heat resistance, mechanical strength, and electrical

resistance compared to butadiene rubber.

| Material Types and General Properties |

| <Table 1>Material types and general properties |

Item

Type | Temp.R ange("C) | Property |

| High Temp.R | Low Temp.R |

| ACM | 150 | -10 | It is used in diaphragm,hose for automotive application.Good

resistance to

heat,ozone and oil.Generally attacked by water,alcohol,glycol and

aromatic

hydrocarbons.The molecular structure contains ethyl

acrylate(EA),butyl acrylate

(BA),and ethyl acrylate(MEA).High BA content get better low

temperature

resistance,and high MEA content get more oil resistance. |

| NR | 70 | -40 | Excellent compression set,high tensile

strength,resilience,abrasion,tear

resistance,good friction characteristics,excellent bonding

capabilities to metal

substrate,and good vibration dampening characteristics |

| VMQ | 225 | 55 | The most widely temperature ranges for application.Good weather and

ozone

resistance,but poor mechanical property and chemical resistance. |

| PTFE | 250 | -150 | Due to the low friction coefficient,it is used in oil seal

lip.However,it is poor

elastic property |

| TPU | 100 | -40 | Polyurethane is one of the groups of elastic thermoplastic

materials.PU has

been used in seal technology for many years because of their

physica

characteristics.It is an organic material of high molecular weight

whose chemical

composition is characterized by a large number of urethane

groups.In addition

it is characterized by extremely good mechanical properties such as

high tensile

strength,abrasive resistance,tear strength,and extrusion

strength.However

t is not resistant to polar solvents,chlorinated

hydrocarbons,aromatics,brake

fluids,acids,and alkalis |

| FKM | | Excellent chemical resistance except ester and ketone |

| 200 | -25 | Dipolymer | Copolymer of vinylidiene fluoride and hexafluoro propylene,and

fluorine content is 66%. |

| -20 | Tripolymer | Copolymer of vinylidiene fluonide,hexafluoro propylene and

tetrafluro

ethylene.Fluorine content is 68%.Tripolymer has better fluid

resistance than dipolymer |

| XNBR | 100 | -40 | Modification of traditional NBR with the insertion of carboxyl

groups

It has better tensile strength,modulus,abrasion than NBR |

3,Standard size